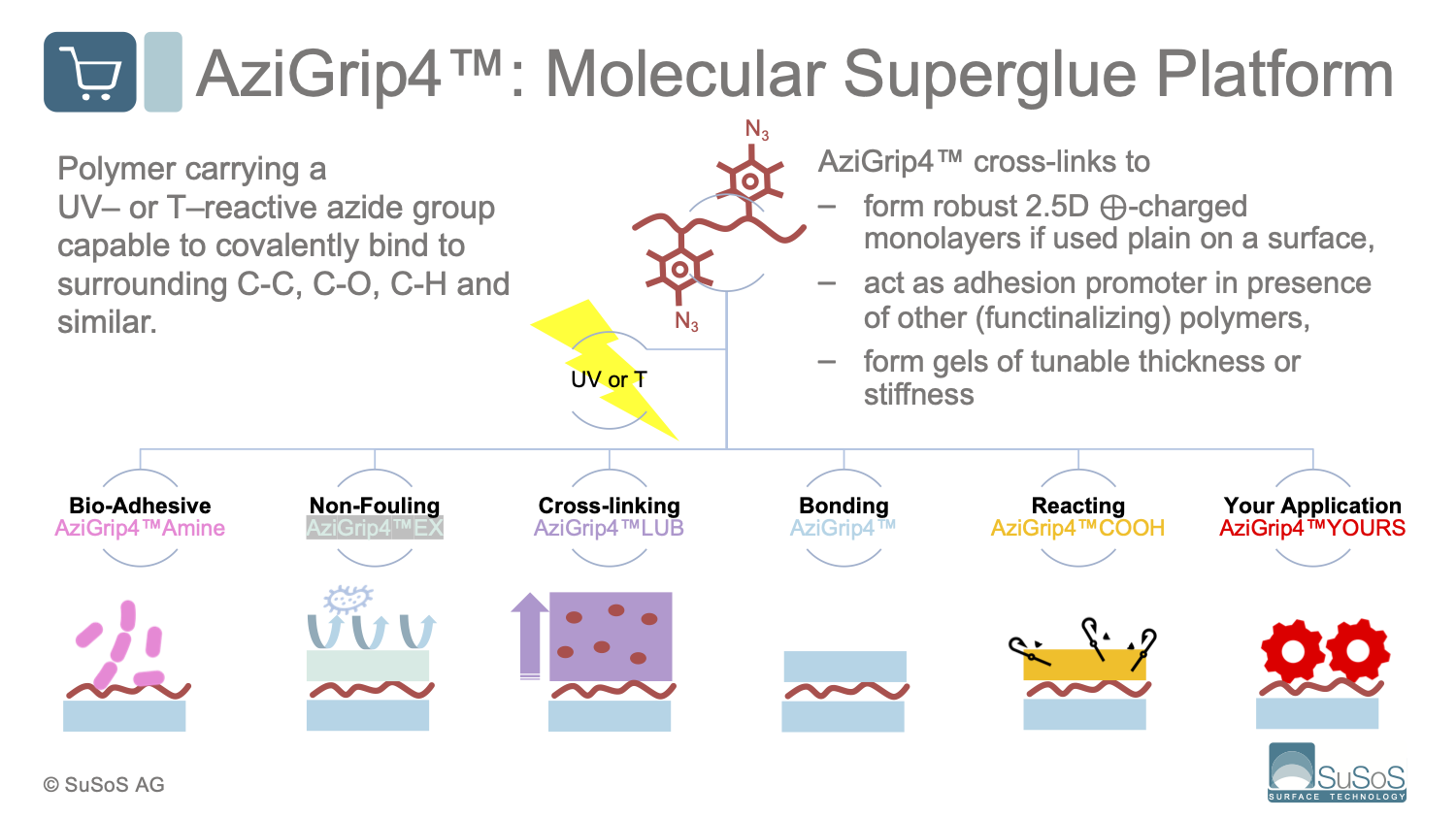

AziGrip4™: azide-based adhesion promoter for advanced surface functionalization.

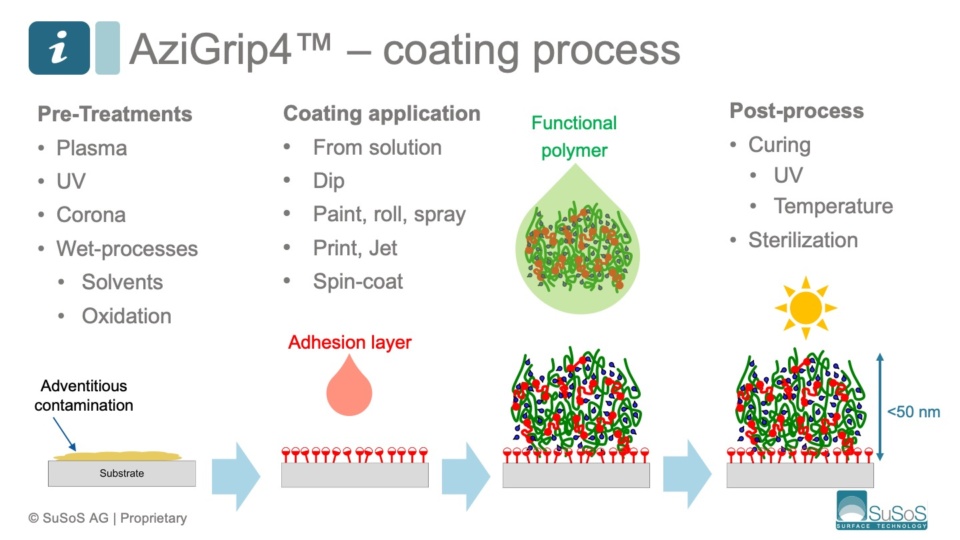

This is AziGrip4™, SuSoS' most employed two-step surface functionalization technology. The AziGrip4™ coating platform is a robust and versatile way to functionalize any surface with polymeric chains.

AziGrip4™ reactive compounds act as a molecular glue between different polymers, hydrogels and/or other materials, such as metals, glass and ceramics.

AziGrip4™ is based on azide groups that are activated by UV-light or temperature to form highly reactive nitrenes. These are capable of undergoing C-H and/or N-H insertion reactions with neighbouring molecules, generating new chemical bonds.

The main advantage of this approach is that the all functionalizations needed for the very application is carried by the AziGrip4™ layer simplifying the otherwise complex chemistry around the device surfaces.

Substrate examples

- Glass, quartz, silicon wafers

- Polyolefins (COC and COP), (plasma-activated) polymers

- Metal oxides (Al2O3, Ta2O5, ITO, TiO2, ZrO2, Fe2O3)

- Silicone rubber, natural latex

- 3D-Printing materials (ABS, Nylon, PLA, PETG, Polyurethane/TPU, PVA, etc.)

Immobilization mechanism

- Electrostatic adsorption followed by a UVC or temperature-induced, cross-linking reaction

- Covalent immobilization on polymeric substrates

Bio-compatibility

- Irritation and Skin Sensitizing evaluated according to ISO 10993-10

- Cytotoxicity evaluated according to ISO 10993-5

- Acute Eye Irritation evaluated according to ISO 10993-10

Shelf-life

- Functional test performed on parts stored in water and air over 5 years

Stability

- Evaluated according to ISO 11357-6

Sterilization

- Compatible with X-Ray/Gamma-Ray, Ethylene Oxide (ETO) and Autoclave

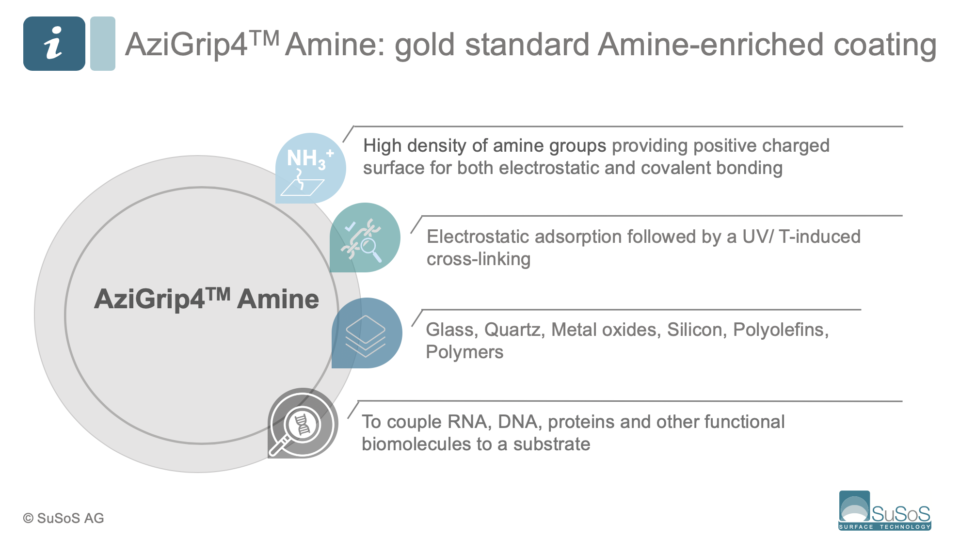

AziGrip4™ Amine, defect-free DNA immobilization coating.

Capture and retain DNA strands during demanding amplification.

AziGrip4™ Amine provides a high density of amine groups providing positive charged surface for both electrostatic and covalent bonding. The coating outperforms standard off-the-shelf chemistries (e.g. silane-amine) by providing an homogeneous and defect-free immobilization carpet for surface-coupled RNA, DNA, proteins and other functional biomolecules in challenging assay conditions.

- Excellent reproducibility at ±2Å over 80k parts produced

- Simple dip-&-rinse process for mono-layer formation

- Multiple attachment via electrostatic binding

- 2.5-D Amine-rich coils for higher functional capacity

- Cross-linked layer for record-breaking stability

Do not hesitate to discuss with us by phone at +41-44-801-80-50 or through the contact form your needs for DNA and protein immobilizing coatings.

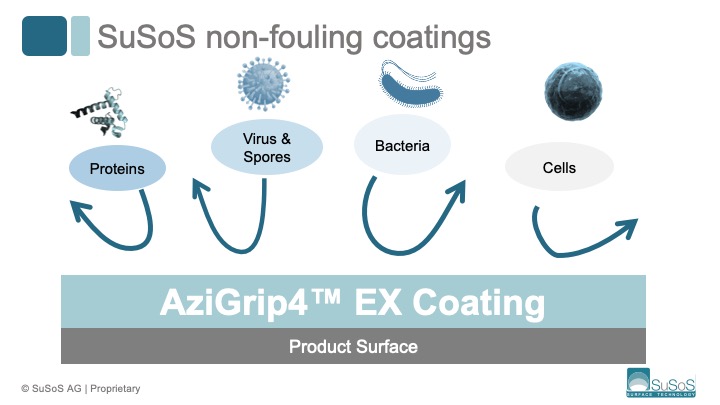

AziGrip4™ EX, robust non-fouling coating.

The versatile non-fouling coating for consumables and microfluidic devices that must undergo sterilization.

AziGrip4™ EX creates a hydrostatic barrier for biomolecules.

Inspired by nature, AziGrip4™ EX inhibits the attachment of bacteria, viruses, cells, proteins and DNA with a permanent aqueous layer at the surface. This impenetrable water layer keeps the surface free from bio-contaminations, whereas alternative, more traditional approaches do actually kill cells or denature proteins leaving the contaminations attached to the surface.

Do not hesitate to discuss with us by phone at +41-44-801-80-50 or through the contact form your needs for non-fouling coatings.

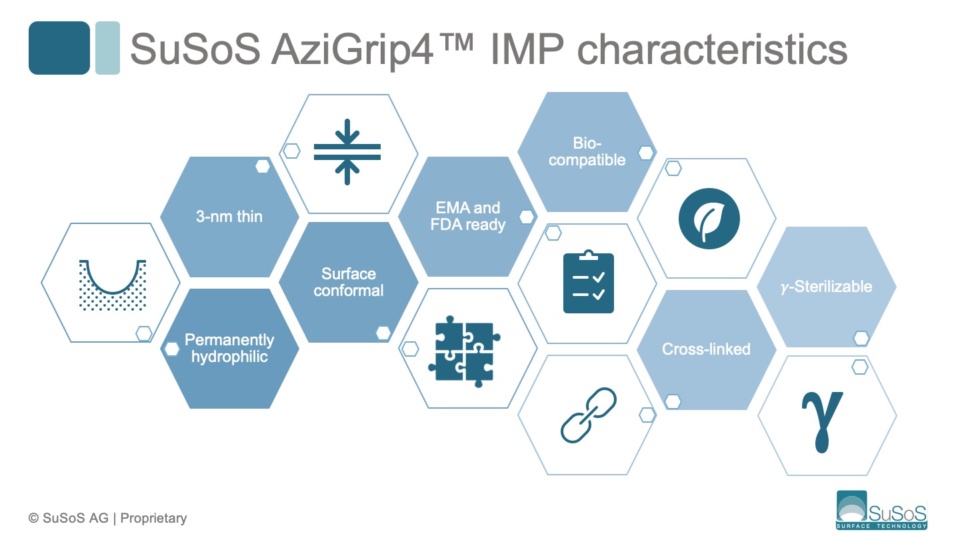

AziGrip4™ IMP, permanent hydrophilicity for implants.

TiOx osteo-integration through permanent hydrophilization of implant surfaces.

Dip, Rinse, Cure. Done.

AziGrip4™ IMP is a simple and convenient extension to the renowned SLA® technology of Straumann, Inc.

The ultrathin, hydrophilic, UV-crosslinked polymeric coating attaches a mixture of positive and negative charges to any metal surface.

This comprehends also sandblasted, large grid, and acid-etched titanium (TiOx).

The permanent hydrophilization at the surface-level makes the transport and storage of implants easy, convenient and totally safe.

Do not hesitate to discuss with us by phone at +41-44-801-80-50 or through the contact form your needs for permanent hydrophilization of metallic surfaces.

- Completes and simplifies installed manufacturing processes

- Industrialized coating process

- Reduced packaging complexity and cost

- Permanent hydrophilic surface

- 𝛾-sterilization compliant

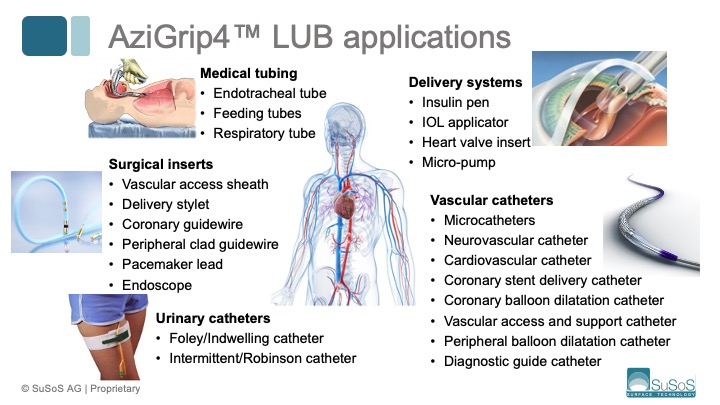

AziGrip4™ LUB, hydrophilic lubricious coating for medical devices

Permanent aqueous lubricating layer covalently linked to your medical device.

With AziGrip4™ LUB you can tune the lubricity of your medical device by controlling the cross linking and thickness of the coating. The coating supplies a thin film of water that is confined to the surface enabling enduring lubricity of the surface. A tailored adhesion layer allows coating anything from metal guide wires to polymer catheters. Due to the unique chemistry it is possible to even coat small inner lumen of devices - a feature of major relevance to minimally invasive surgery.

Features of the AziGrip4™ LUB hydrophilic lubricious coating include:

- Benchmarked ultra-low friction - COF = 0.005

- Customizable coating thickness

- Reduces biofilm formation e.g. blood coagulation, bacterial infections

- Silicone and fluorinated-polymer free

- Strongest possible covalent binding even inside tubes

- Minimum particle generation

Contact us to learn how your medical device can benefit from tuned lubricity via AziGrip4™ LUB - by phone +41-44-801-80-50 or through the contact form.

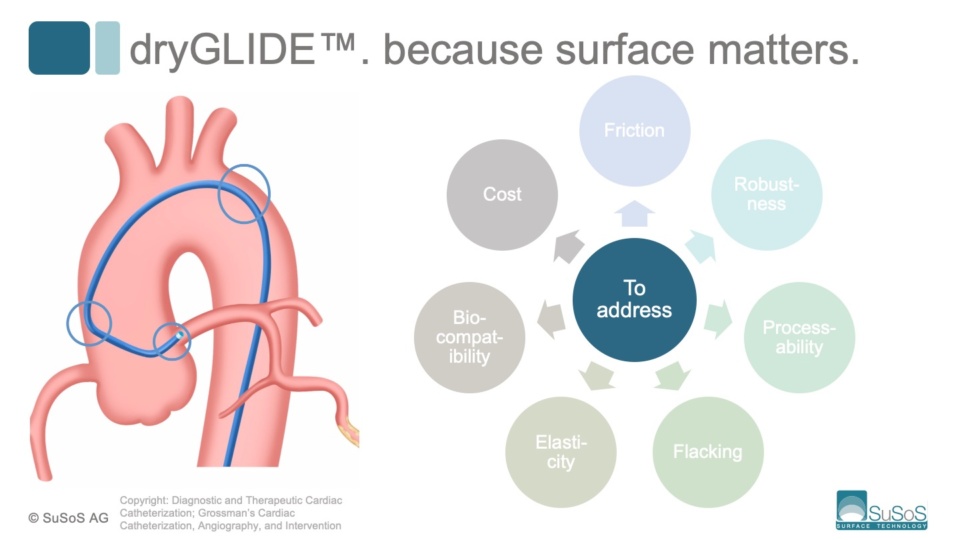

dryGLIDE™, tunable, self-lubricious medical coating.

SuSoS' dryGLIDE™ carries a non-aqueous lubricant that delivers adjustable lubricity. And can carry medicaments.

Order, unpack, use. Done.

dryGLIDE™ is sterile by design and does not need any wetting right before use to guarantee lubricity.

– Adjustable friction to enable complex procedures.

– No wetting required to reduce the risks of infection.

– No slipperiness for easier handling, better touch feedback.

– Constant lubricity for guidewires that do not get stuck on dry spots.

– Silicone-free and PTFE-free.

Whether controlling the glide, the haptic feedback, the torque, the ability of following the vascular geometries or to properly carrying catheters and stands, wire guides treaded with dryGLIDE™ outperform their traditional alternative technologies with no compromises.

Do not hesitate to discuss with us by phone at +41-44-801-80-50 or through the contact form your needs for self-lubricious treatments of your cardiovascular catheters.

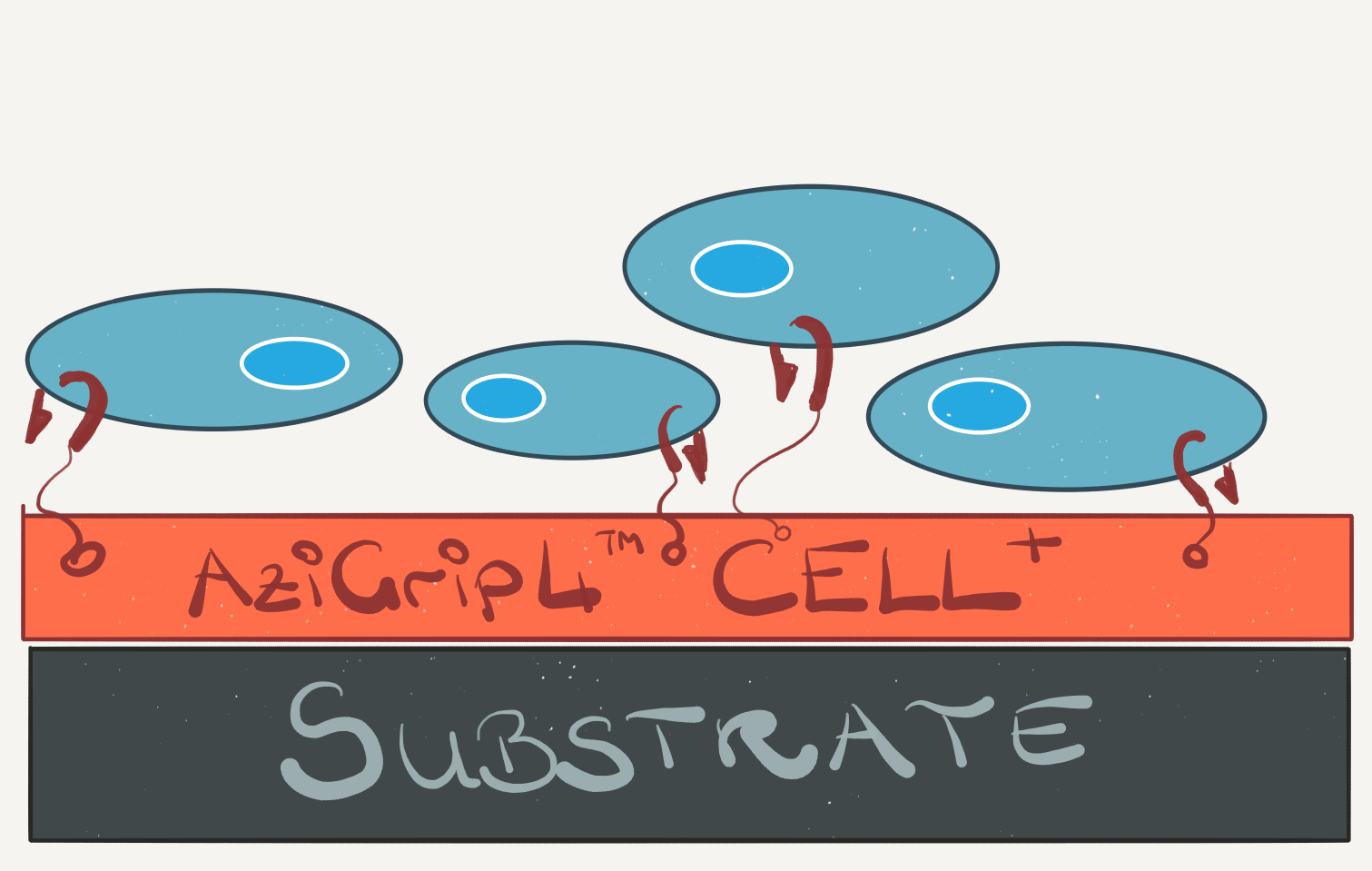

AziGrip4™ CELL+, enhanced homogeneous cell adhesion for life-science applications

Highly cell-adhesive carpet that makes life-science experiments consistent.

AziGrip4™ CELL+ is a specially designed surface treatment that homogeneously improves the cell adhesion to the targeted substrate resulting in simplified and standardized procedures to test cells and compounds in laboratories and preclinical studies.

We call AziGrip4™ the molecular superglue: toward the substrate… and toward the objects to be dealt with.

Without interfering with the potentially very delicate substrates that cells shall thrive on, AziGrip4™ CELL+ provides a homogeneous functionalization layer that cells particularly appreciate and link to.

AziGrip4™ CELL+ provides simplification, standardization and consistency in cell culture applications.

Contact us to learn how your life-science device can benefit from enhanced cell-adhesion homogeneity via AziGrip4™ CELL+ - by phone +41-44-801-80-50 or through the contact form.

AziGrip4™ YOURS, tailored coating for your very application.

AziGrip4™ can be combined virtually with any polymeric functionalization. Talk to us to find out how we can help you.

The AziGrip4™ technology is covered by international patents controlled by SuSoS. AziGrip4™ is a SuSoS trade mark. All rights reserved.