Do not hesitate to discuss with us by phone at +41-44-801-80-50 or through the contact form your needs for anything related to tailored adhesion, specific binding, broad-band bio-resistance or your specific application.

Broadband Non-fouling

Preventing biomolecule attachment to surfaces.

SuSoS’ non-fouling coatings reduce protein-background in point-of-care in-vitro diagnostics, create low-retention surfaces in stem-cell culture consumables, and prevent undesired biofilm formation in organ-on-chip platforms.

To provide an optimal non-fouling function on your products our coatings:

- Create a hydrostatic barrier towards biomolecules

- Continuously prevent unspecific biomolecule binding

- Operate free of active ingredients (e.g. silver, heparin, etc.)

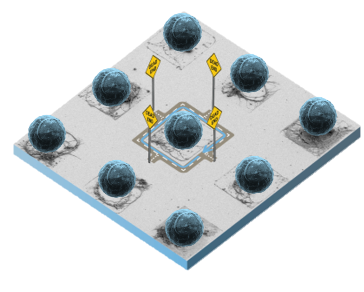

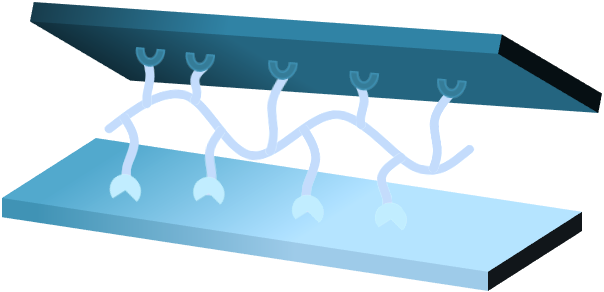

Non-fouling surfaces are very important in organ-on-a-chip (OOC) plates, for undifferentiated organoid formation and 3D cell culture well plates and wherever the attachment of bio-materials, proteins or cells is harmful to the applications, such as in bioreactors or micro-pore membranes.

Typical issues caused by attachment of bio-material to surfaces are: default to 2D/surface crawling of cells, micropore clogging, high-noise signals in bio-sensors, fouling, bubble formation, bio-contamination, erratic experiment behaviors and more.

By the use of SuSoS' AziGrip4™ or PAcrAm™ coating platforms to apply a non-fouling layer on your device, we offer polymeric carpets that resit extreme pH conditions, mechanical deformation, ionic solutions, ethanol or γ–sterilization procedures and other harsh environments.

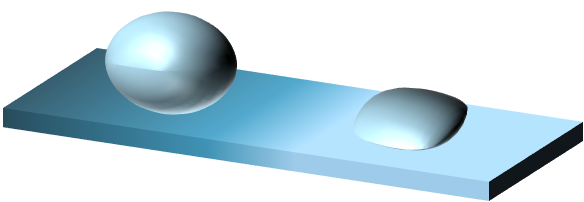

Formation of spheroids in special wells coated with AziGrip4™ EX. Copyrights with the copyright holder.

Specific Bio-functionalization

Ensures that only what you need to adhere, does. Consistently. Exclusively.

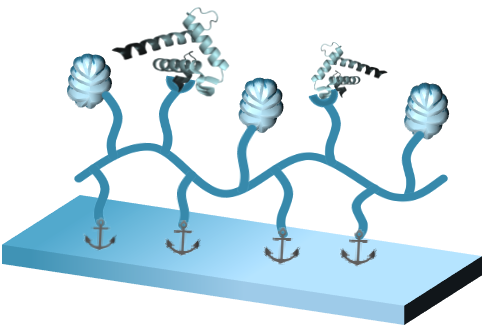

Surfaces in diagnostic applications such as in-vitro diagnostic assays or proteomics frequently depend on capturing exclusively a target molecule of choice. A the same time it is critical for a diagnostic surface to repel any unspecific interactions of other moieties present in the test solution.

To achieve this challenging combination of properties the surface SuSoS bio-functional coatings combine:

- Highly specific binding sites for target moieties

- Ultra-low unspecific binding through non-fouling groups

- Covalent biomolecule immobilization via Click-chemistry

- Minimal effect on autofluorescence

A range of point-of-care (POC) in-vitro diagnostic (IVD) tests for infections and allergies benefit from SuSoS bio-functional coatings based on AziGrip4™ and PAcrAm™ coating technologies.

Controlled Cell Adhesion

Enabling and enhancing the adhesion of cells where you really need them to be. Or not to be.

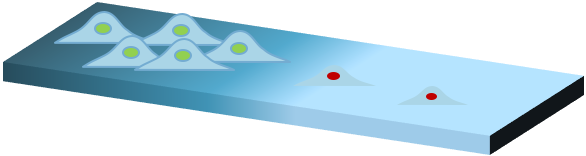

Products in life sciences demand for surfaces tuned to control the cell-surface interactions carefully. Key parameters can include confining cell-attachement or guiding and stimulating cell-growth. In cell-culture consumables, microfluidic lab-on-chip devices or products in regenerative medicine providing stable and controlled surface functionalities can define product performance.

To provide optimal surfaces for cells SuSoS coatings enable:

- Patterned and domain-specific cell attachment

- Peptide-mediated growth stimulation

- Surface passivation for zero-in

A range of products including temporary or permanent implants, cell-culture consumables, microfluidics and lab-on-chip devices benefit from AziGrip4™ and PAcrAm™ coatings. If your product requires a tailored interface for cells to develop - you have reached the right address.

Adjusted Wettability

Controlling the surface energy means controlling adsorption, absorption and fluidic dynamics.

The ability for a liquid to wet a surface can be critical, considering our eyes as a natural best practice reference. Whether it is a glue that can not be applied homogeneously or a microfluidic channel that does not fill homogeneously – wetting can be a critical surface property.

Tuning the surface energy using functional monomolecular layers allows us to control the wettability of surfaces. Extreme examples of tuned wettability include

- gradient-coatings moving water drops upwards against gravity

- permanently hydrophilic Teflon®/PTFE or Polypropylene (PP)

SuSoS coating platforms AziGrip4™ and PAcrAm™ enable controlled wettability of product surfaces.

Bubble Removal

Enabling easy and complete filling of fluidic micro-channels enhancing the withdrawal of bubbles.

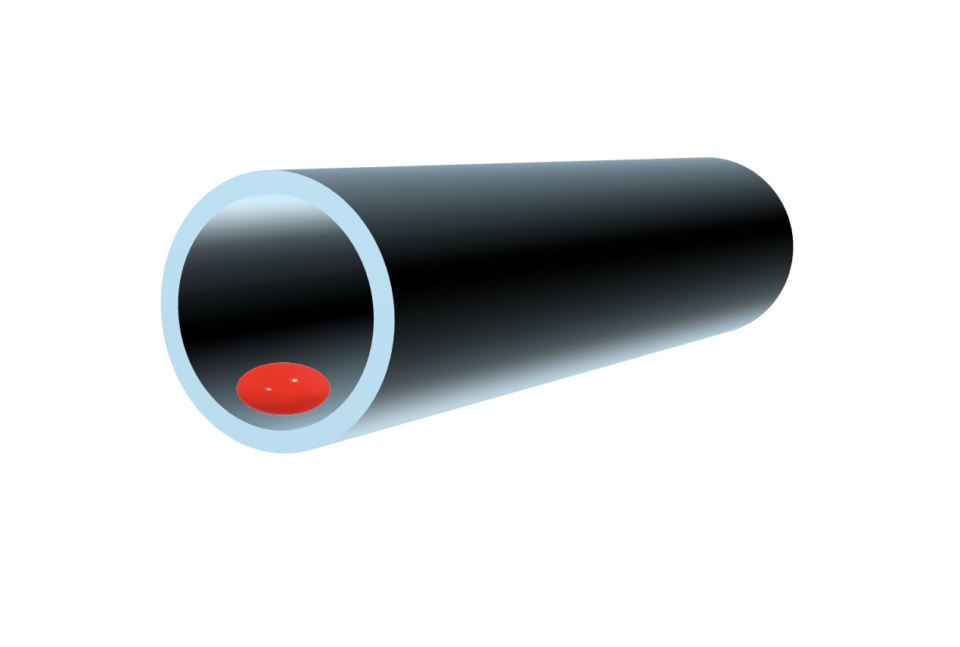

Transporting fluids bears the inherent risk of introducing bubbles into a system. Bubbles can cause failures orworse affect the outcome of a test or experiment performed. The surfaces of closed fluidic systems are hard to change by conventional means (e.g. Plasma treatments, Vapor depositoin) frequently causing issues in products such as: microfluidics chips, blood diagnostic tests or flow sensors.

The coatings of SuSoS can be introduced both before assembly of devices as well as into closed devices to selectively decorate inner lumen. The ability to introduce permanent hydrophilicity or hydrophobicity allows to prevent and effectively remove bubbles.

Introduce AziGrip4™ and PAcrAm™ coatings to your closed or open devices to prevent bubbles from forming and/or adhering.

Tunable Lubricity

Adjusting the lubricity of surfaces to find the sweet spot between smoothness and haptic feedback.

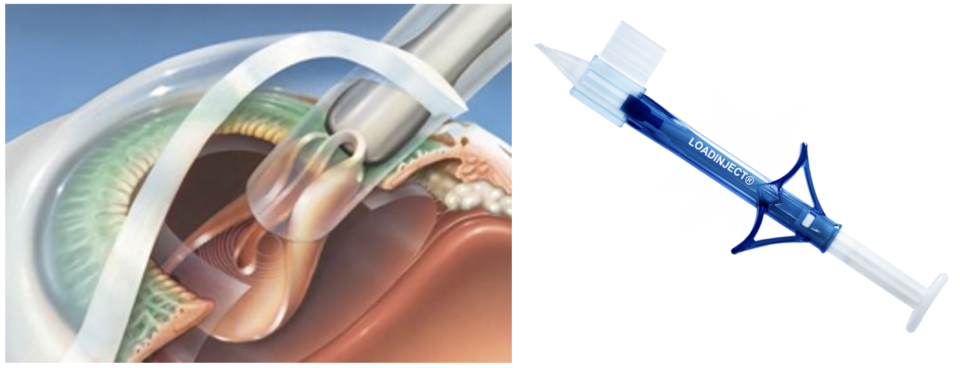

Intra-ocular-lens (IOL) injector cartridges coated with AziGrip4™ LUB - Courtesy of MDJ SAS.

Lubricity of medical devices can be critical to patient treatment, consider a guide-wire passing a narrow blood-vessel. While low friction is desirable, often a certain degree of friction is required for adequate haptic feedback for surgeons. The functionalities typically desired in a hydrophilic lubricious coating include:

- Tailored friction for optimal performance

- Free of silicone and fluorinated polymers for regulatory compliance

- Strong covalent binding even on complex geometries or small inner lumen

- Minimum particle generation in use

SuSoS proprietary hydrophilic lubricious coatings enable custom designed surface solutions to advance best-in-class products including:

- vascular guide-wires for optimal navigation in vessels

- neurosurgical micro catheters for minimal tissue damage

- ophthalmic intra-ocular-lens injectors for minimally invasive incisions

If your product can benefit from a tuned friction performance, learn more about our AziGrip4™ hydrophilic lubricious coatings.

Bonding anything to anything.

SuSoS molecular superglues firmly bond glass-2-glass, glass-2-polymer, polymer-2-polymer, anything-2-anything.

Bonding of challenging interfaces requires a deep understanding of the chemistry involved. SuSoS employs its unique expertise to enable bonding of materials pairs - beyond conventional solutions. We customise molecular superglue polymers with specific functionalities to attach to both sides of an interface and thereby create strongest possible bonding.

To make materials adhere to one-another we:

- Create tailored molecular level adhesion-interfaces

- Provide permanent chemical priming (e.g. hydrophilisation)

- Develop dedicated bonding-processes (e.g. low-temperature bonding)

Are you seeking a technical solution to a challenging bonding interface or a dedicated glue to enable bonding performance? Then the AziGrip4™ coating platform could be the solution you are looking for.

Not found what you are looking for?

Have a look at the following additional selection of surface-related topics and feel free to contact us.

Different substrates, different opportunities. And features. Read more below…

Beyond the highly specialistic applications SuSoS is mostly active in, technical coatings are present in a variety of objects and situations. Read more below…

Product surfaces can be challenging in many ways - here we list just a few.

SuSoS coatings are inspired by the ability of nature's water based lubrication systems. Mimicking functions used by snails, humans and plants - SuSoS lubricious coatings provide ultra-low friction surfaces for modern medical devices such as injectors for intra-ocular lenses or catheters.

Learn more about our hydrophilic lubricious coating platforms AziGrip4™.